Sustainability

Our Supply Chain

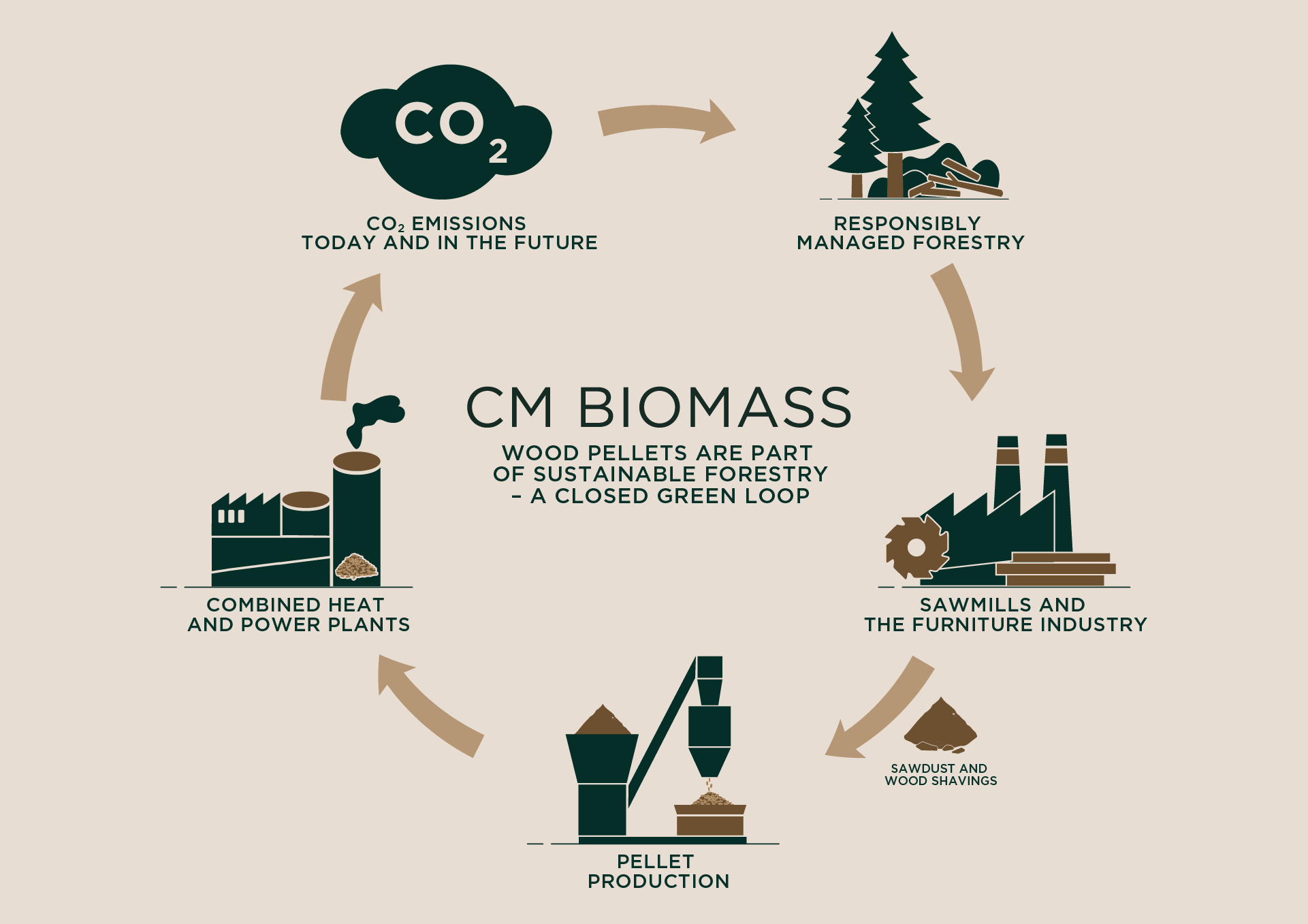

Wood pellets are part of sustainable forestry – a closed green loop.

- The first step in the value chain occurs in the forest where the trees are harvested.

- To produce timber, furniture, etc., the forest must be managed and thinned to obtain logs of the right quality.

- CM Biomass does not own or purchase forests for pellet production.

- Residues can be used for paper or for energy purposes such as wood pellets, making it economically more advantageous to manage and/or establish forests. All wood pellets produced by CM Biomass are based on by-products.

- The forest owner gets the most value for their wood when the logs are sold to the construction and furniture industries.

- The logs are sent to the sawmill, where they are first cut into beams and wood for the furniture industry. After that, the residual wood is used for smaller products such as packaging materials.

- Both at the sawmill and at the furniture factory, a residual material is generated in the form of sawdust and wood shavings.

- Pellets are made from compressed wood shavings and sawdust.

- Thus, the residues that would otherwise remain unused is efficiently utilised for producing wood pellets.

- This benefits both the economy of forestry and contributes to greener energy and heat production.

- A large portion of the wood pellets is used as fuel in in combined heat and power plants (CHP).

- Here, the wood pellets replace coal or natural gas when the energy in the wood pellets is converted into heat and electricity for consumers and industry.

- Although some wood pellets are transported over long distances, e.g. from the USA, saving in CO2 emissions is about 80-90% compared to fossil fuels.

- Today CO2 is released into the atmosphere when the wood pellets are burned at the CHP, after which it can again be captured by trees during photosynthesis.

- CHPs in several countries are establishing carbon capture facilities in the coming years, making it possible to capture CO2 directly at the plant.

- The captured CO2 can either be stored underground, or

- Potentially be used as a feedstock for production of fuels for the aviation and shipping sectors.

1

1

Responsibly Managed Forestry

- The first step in the value chain occurs in the forest where the trees are harvested.

- To produce timber, furniture, etc., the forest must be managed and thinned to obtain logs of the right quality.

- CM Biomass does not own or purchase forests for pellet production.

- Residues can be used for paper or for energy purposes such as wood pellets, making it economically more advantageous to manage and/or establish forests. All wood pellets produced by CM Biomass are based on by-products.

- The forest owner gets the most value for their wood when the logs are sold to the construction and furniture industries.

2

2

Sawmills and The Furniture Industry

- The logs are sent to the sawmill, where they are first cut into beams and wood for the furniture industry. After that, the residual wood is used for smaller products such as packaging materials.

- Both at the sawmill and at the furniture factory, a residual material is generated in the form of sawdust and wood shavings.

3

3

Pellet Production

- Pellets are made from compressed wood shavings and sawdust.

- Thus, the residues that would otherwise remain unused is efficiently utilised for producing wood pellets.

- This benefits both the economy of forestry and contributes to greener energy and heat production.

4

4

Combined Heat and Power Plants

- A large portion of the wood pellets is used as fuel in in combined heat and power plants (CHP).

- Here, the wood pellets replace coal or natural gas when the energy in the wood pellets is converted into heat and electricity for consumers and industry.

- Although some wood pellets are transported over long distances, e.g. from the USA, saving in CO2 emissions is about 80-90% compared to fossil fuels.

5

5

CO2 Emissions Today and In the Future

- Today CO2 is released into the atmosphere when the wood pellets are burned at the CHP, after which it can again be captured by trees during photosynthesis.

- CHPs in several countries are establishing carbon capture facilities in the coming years, making it possible to capture CO2 directly at the plant.

- The captured CO2 can either be stored underground, or

- Potentially be used as a feedstock for production of fuels for the aviation and shipping sectors.

Let's Talk

Copenhagen / Denmark

CM Biomass Partners A/S

Sundkrogsgade 11, 2. 2100

Copenhagen / Denmark

+45 3226 0300

Register your Interest

Thank you for your interest in CM Biomass. We are committed to being a reliable partner in your renewable energy journey.

Whether you are a customer seeking biomass solutions or a new supplier interested in collaborating with us, we are here to provide the support and expertise you need.

Please fill out the form and we will respond promptly. We look forward to building a successful partnership with you.